Day 2, Skin on frame rower-sailer. Build time: 6hrs. Made stems, set up the keel, milled ribs, built a new steam box. The hardest part about prototyping new boats is the gnawing uncertainty that is constantly begging me to stop mid-build and change course. Like right now, I’m damn near certain that I’d be...

"Day 2: Skin-on-frame rower-sailer"Continue readingCategory: Building Notes

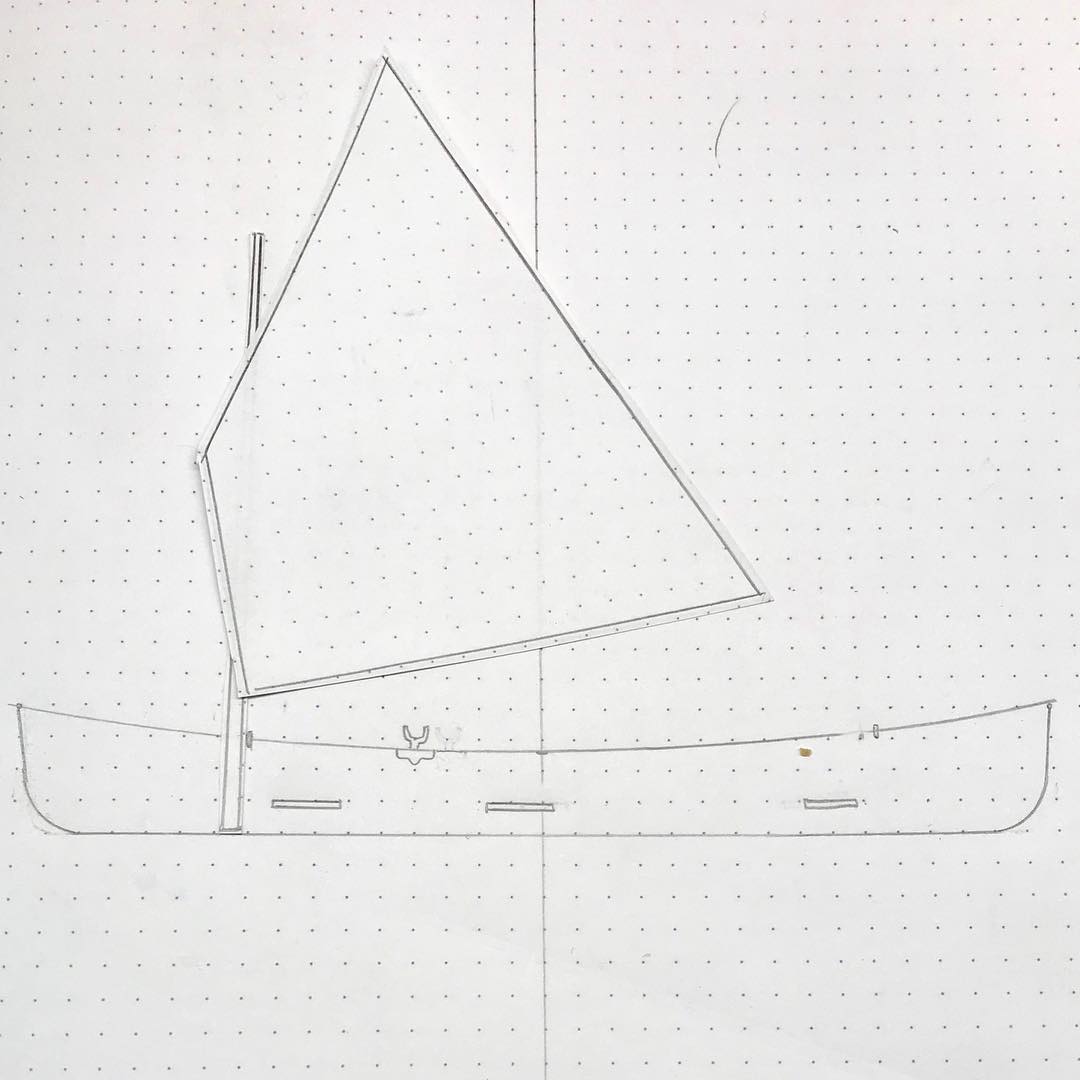

Day 1: Skin-on-frame rower-sailer

This week I’m taking a wild stab at putting together a little rowing/sailing canoe using the fast easy system that I developed last year for building pack canoes. My hope is to eventually develop a nice little rower that is a lot easier to build than my beloved skin-on-frame Adirondack Guide boats. This boat...

"Day 1: Skin-on-frame rower-sailer"Continue readingBuilding steam bent kayak cockpit coamings

We all have that one work thing we absolutely hate. You know what I mean, that thing that isn’t really that hard but for whatever reason you just dread. For me it’s making steam bent keyhole kayak cockpit coamings. One of the biggest challenges when I first started designing skin on frame kayaks was...

"Building steam bent kayak cockpit coamings"Continue readingVideo: Outfitting the 66 canoe

Seating, flotation, portage yoke, sails, outriggers.... All the bits and bobbles that turn a bare hull into a useable watercraft....

The simultaneous wonderful and terrible thing about being a boat builder is that you can build whatever you want.

The simultaneous wonderful and terrible thing about being a boat builder is that you can build whatever you want. If you have access to a sawmill and like to play around with design the problem is even worse. Next up on my actual work schedule is a St. Lawrence River skiff but for whatever...

"The simultaneous wonderful and terrible thing about being a boat builder is that you can build whatever you want."Continue readingVideo: A short overview of the canoe building process

To celebrate the release of our new online skin on frame canoe building course I took some time today to mix down a few short videos of the process. Enjoy!...

On YouTube: a visual walkthrough of the entire process of building a skin on frame canoe

New video up on the YouTube channel: a visual walkthrough of the entire process of building a skin on frame canoe, from selecting the wood to paddling the boat. ...

Salvage canoe paddle: Part 2

Salvage canoe paddle: Part 2, Found a broken coffee table on the side of the road and couldn’t resist. Shaft, Douglas fir. Blade, some wood I had hoped was Cherry, but wasn’t....

Salvage canoe paddle: Part 1

Salvage canoe paddle: Part 1 Found this broken coffee table on the side of the road and couldn’t resist. Shaft, Douglas fir. Blade, some wood that I had hoped was cherry, but wasn’t....

Anybody can make something that’s pretty and curvy looking, but how does it perform?

Anybody can make something that’s pretty and curvy looking but my passion is focused on how it performs in the water. When it comes to understanding something there is simply no substitute for experience. This is the 12th canoe I’ve built since May. It’s built with white oak ribs, red cedar gunwales and upper...

"Anybody can make something that’s pretty and curvy looking, but how does it perform?"Continue readingVideo: Trimming the fabric

Trimming the fabric. The sound on this one is kinda neat!...

Skinning day

Skinning day is such a beautiful part of the skin on frame process. So many gorgeous visuals....

Allowing for height and angle adjustability in canoe seats

One of the cool things about these new skin on frame canoe designs that I’ve been working on is that the solid laminated gunwales provide a beefy enough surface to hang seats the same way you would in any canoe. This allows for the same kind of height and angle adjustability that you normally...

"Allowing for height and angle adjustability in canoe seats"Continue readingCoating the skin

Coating the skin. I use a 9oz ballistic nylon skin on most of my boats, coated with a 2-part polyurethane - aka "goop". It takes a few hours to apply a few coats of goop, cures for 24 - 48 hours, and done....

Video: continuous lashings

People often ask me if the continuous lashings I use are vulnerable to breaking. The answer is that in 17 years of doing this I’ve never had one break, but it wouldn’t matter if it did because the coating essentially glues the skin to the frame effectively trapping and isolating each lashing. Nothing wrong...

"Video: continuous lashings"Continue reading