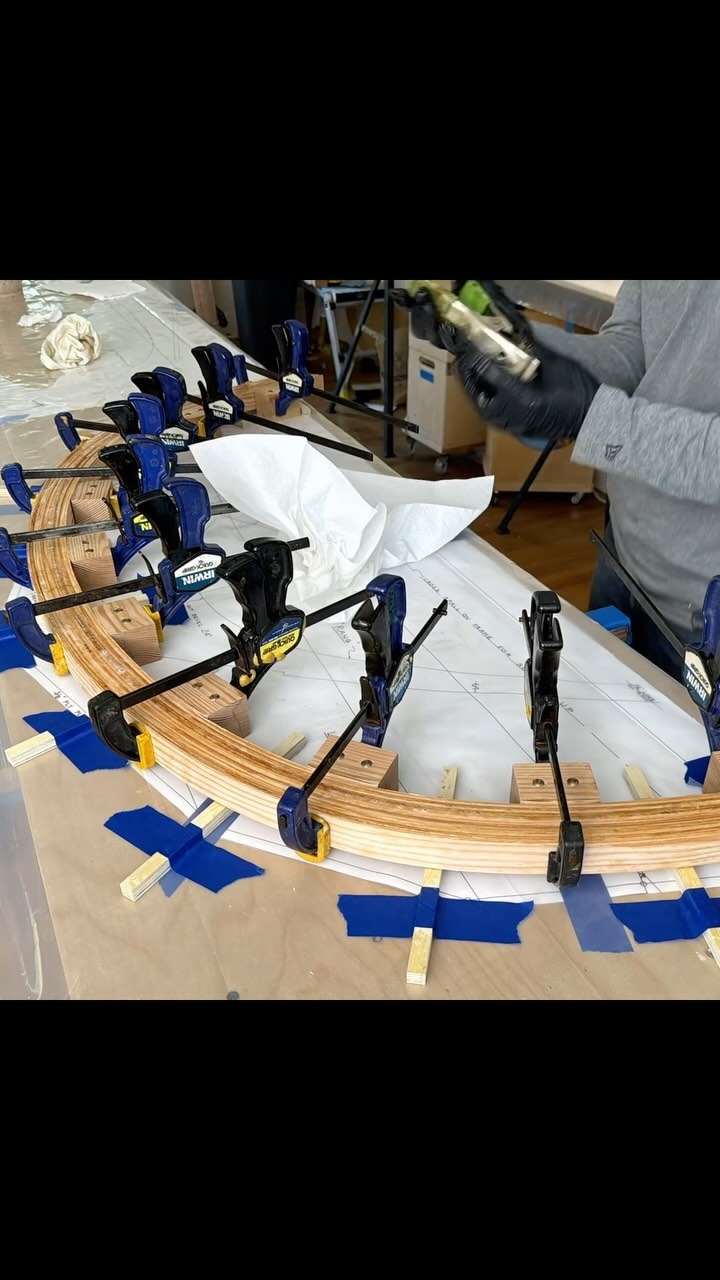

Skin on Frame Shearwater build, day 7, 6hrs Cutting the outer keel curve and gluing up the scarfs Today I finally finished the inner and outer keel assembly, which honestly took about three times as long as it really needed to but checking everything 10 times takes a bit of time. I’m sure this...

"Video: Skin on Frame Shearwater build, Day 7"Continue readingCategory: Row / Sail

Video: Skin on Frame Shearwater Build, Day 6

Skin on Frame Shearwater Build, Day 6, 6hrs. Building the keel assembly, Part 1 With all the laminations finally done, I was able to clear off the layout table and start building the inner/outer keel. This part is taking me a lot longer than it really needs to, but I haven’t done this before...

"Video: Skin on Frame Shearwater Build, Day 6"Continue readingVideo: Skin on Frame Shearwater build, Day 5

Skin on Frame Shearwater build, Day 5, 2hrs Nothing terribly exciting here today. Just spent a couple hours sorting through lumber and cutting it into strips then cutting tapers, then gluing it up into longer lumber for the gunwales and the upper stringer. For these particular joints, I thickened the epoxy to about the...

"Video: Skin on Frame Shearwater build, Day 5"Continue readingVideo: Skin on Frame Shearwater build, Day 4

Skin on Frame Shearwater build, Day 4, 3 hrs After cleaning up the inner stems with a power planer and squaring the front face, I put a strip of packing tape on the front curve to prevent adhesion and then cut up some beautiful lightweight mahogany (who knows what this actually is?) and laminated...

"Video: Skin on Frame Shearwater build, Day 4"Continue readingVideo: Test cuts for the Shearwater keel

The shearwater will be my first non-laminated, inner and outer curved keel. These have to match perfectly and I didn’t love the idea of cutting one and then scribing the line onto the other and then praying that I could follow that same line to within a 64th. So here I am doing an...

"Video: Test cuts for the Shearwater keel"Continue readingSkin on Frame Shearwater build, Day 3

Skin on Frame Shearwater build, Day 3, 4hrs Today we laminated the two intermediate frames, which is a process you’ve already seen, so I figured why not use this space today to show you what the Shearwater looks like built as designed out of glue lap plywood. This particular Shearwater was built by Bill...

"Skin on Frame Shearwater build, Day 3"Continue readingTimelapse: Shearwater stem and frame laminations

Sound on! As long as I have the forms for the shearwater set up on my work tables, I figured I might as well laminate up a second set of stems and frames in case I ever want to build another one. So that brings me up to 10 large laminations, which has really...

"Timelapse: Shearwater stem and frame laminations"Continue readingVideo: Skin on Frame Shearwater build, Day 2

Skin on Frame Shearwater build Day 2, 3.5hrs Today’s lamination went really well. I used West System epoxy with the 207 hardener which gave us plenty of open time in the 100 degree heat. This is my first time working with West system and it’s definitely more expensive, but I really like the pumps...

"Video: Skin on Frame Shearwater build, Day 2"Continue readingVideo: Skin on Frame Shearwater build, Day 1

Day 1, Skin on Frame Shearwater build. 5hrs I can’t tell you how happy I am to be starting a new design project! (unfortunately most of my time is spent doing administrative stuff for the business) I’ve built a handful of rowing and sailing boats in the past but I’ve never been able to...

"Video: Skin on Frame Shearwater build, Day 1"Continue reading